In the pantheon of cool axle tech, there is one axle that stands above the rest. Literally. Portal axles give you built in lift height, better clearance under the differential and can increase available power delivered to the tires with extra gear reduction.

The portal axle solved the problem of how to build a bulletproof axle that still had good ground clearance for obstacle avoidance. One interesting tidbit about this off-road developed technology is where they have actually been used the most. Ever gotten on a city commuter bus? Yep, the biggest user of portal axles technology is the utilitarian people mover. By flipping the axle you can lower the floor of the bus closer to the ground. It’s pretty genius.

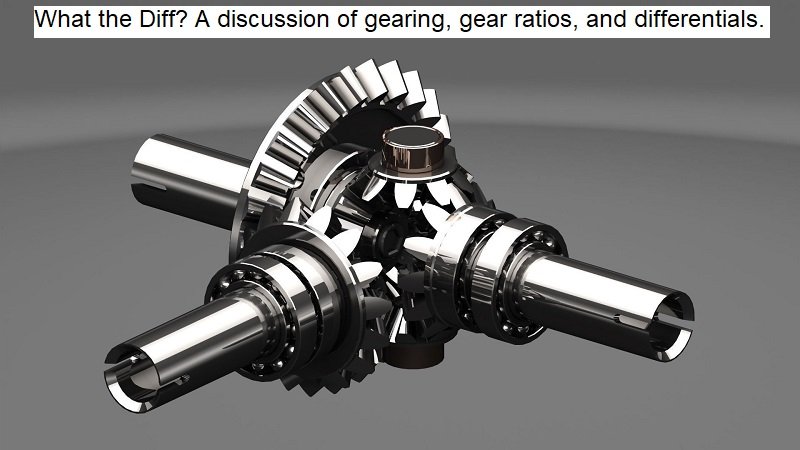

But what are portal axles?

Take a normal axle and attach a set of gears on either end so you can move the output to the wheel and tire below the centerline of the axle.

As you can see there are three gears that transfer the force of the axle shaft to the output on the portal box. A three gear setup is used to allow the output to the wheels to spin the same direction as the axle. If not the vehicle would travel in the opposite direction. The gear ratios used also provide additional gear reduction multiplying the force delivered at the wheel.

So why aren’t portal axles on every off-road vehicle?

There are of course trade-offs whenever you reinvent the wheel. The gears used in portal boxes are straight cut. Because of the amount of force applied anything else would get chewed apart too rapidly. That means the average portal box is louder than a set of Swampers on the highway.

Portal axles weigh a ton when compared to their traditional counterparts. How could they not, they are a full normal axle with two extra sets of gears and housings. They are expensive, ex

Converting a vehicle to portal axles requires a lot of suspension reengineering to get the geometry back to the correct steering and suspension angles. If you don’t you will only exacerbate death wobble and wandering steering.

At this time there isn’t an aftermarket solution to allow the use of speed sensors, parking brakes, or ABS.

What’s the future hold?

Portal axles have found a new niche and are becoming very common in the performance UTV market. With the added strength, built-in lift height, and an increase in vehicle width they are a great fit on a UTV.

All of the arguments above are invalidated with a UTV. They don’t generally see any road use, the independent suspension doesn’t suffer from the steering or geometry issues, and there aren’t the complex sensors many modern road vehicles have.

All is not lost.

There are quite a few aftermarket companies working on different solutions to bring portal axles to the masses. Atomic axles are one such company. Combining half shaft technology with a unique housing and portals to give a new hybrid solution to portal boxes slapped on an existing axle or swapping in Unimog axles.